|

Photo Page:

current versions

|

|

version #2 cd cases in place to extend baffle because the left-over pieces from the version #1 larger baffles fit perfectly into the 6"pvc ! lololo

|

i have mistakenly posted that the driver is a 5" but it is actually a 4" !

|

the other end is just as short ! lolol

|

|

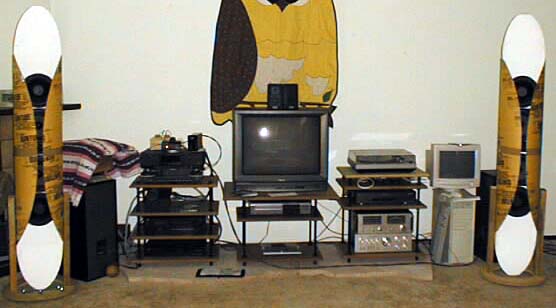

6"pvc x 48" 2-way speakers 35" from rear wall/10' apart and 12' each from listening position.

|

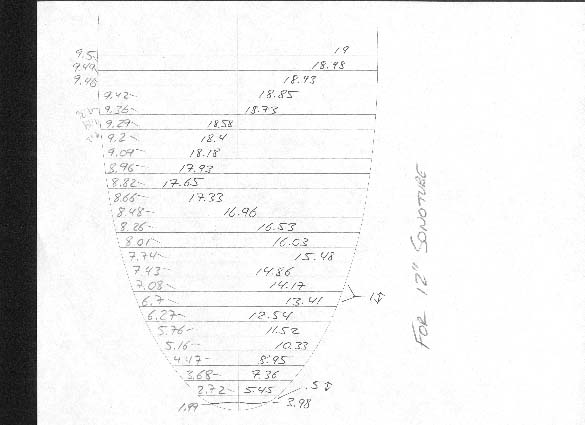

plot for 12" x 48" tube

|

view inside 12" tube prior to cutting k-slots showing center hole for 8" driver..

|

|

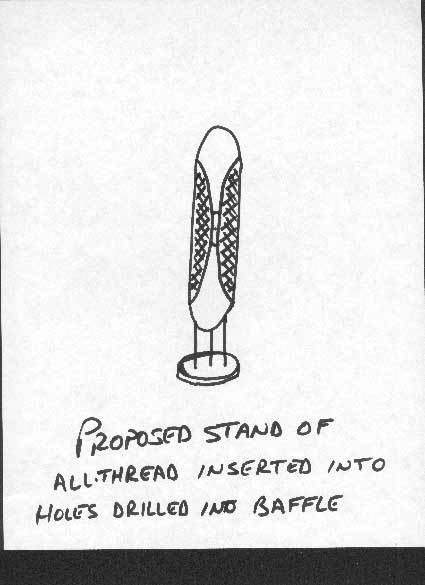

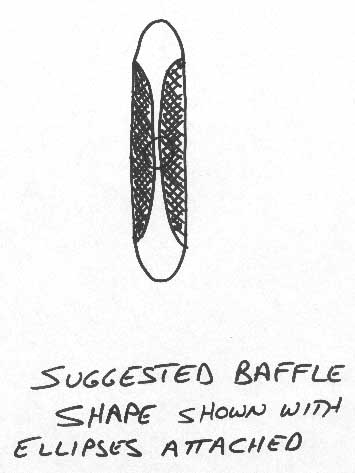

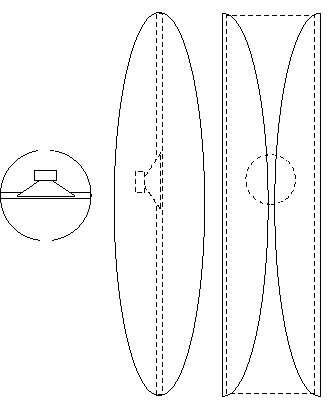

proposed stand and baffle shape for further smoothing transition of k-slot to room.

|

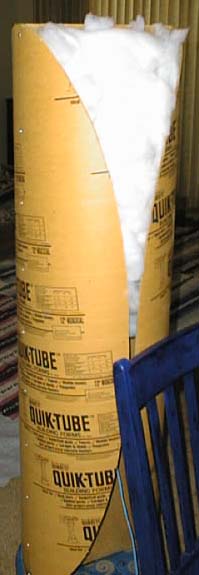

back of tube showing polyfill stuffing.

|

back of tube shown prior to stuffing.

|

|

12" tubes with single full-range 8" driver rs 1286c with about 2lbs plumbers-putty on magnet/basket and thick felt sections glued to inside of basket legs. also has 6 coats of rave super-hold on cone and 3 coats on whizzer.

|

early idea for speaker

|

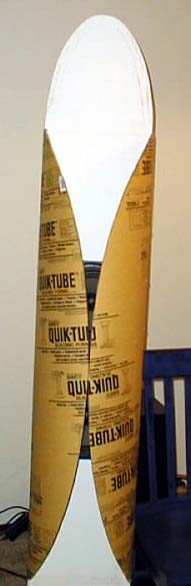

12" tubes with baffles mounted and prior to cutting k-slots.

|

|

excellent illustration done by jrutter. thanks jr !!

|

version #5 rs1297c in 10"x6'pvc

|

1/2"pvc sched 200 on platter and 3/4"pvc sched 40 attached to vacuum motor. note o-ring on 1/2"pvc section that slides into the 3/4"pvc vertical section. the o-ring fills the gap and makes a seal.

|

|

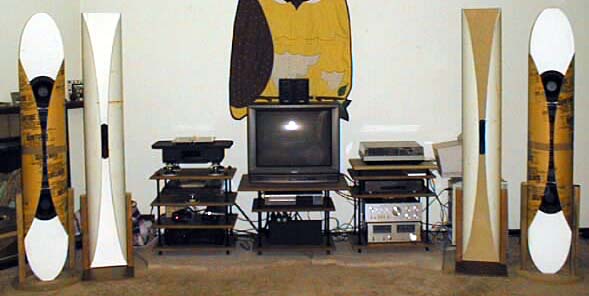

speakers in place for listening and b&w cabinets visible that still contain the xover. k-slot was closed at the center at first but is now open 3/4" as this is the smallest opening a 20khz wave can pass through and the imaging became more focused.

|

rs1297c speakers currently being used for ht system

|

original perforated canister wrapped in duct-tape to make vacuum chamber. note ground-screw attached to pvc fitting for discharging static through powercord ground. polyfill stuffing is for sound absorption. vacuum chamber is also filled with polyfill for absorption/evaporation of fluids. may add capture-jar later.

|

|

version #3 showing the 2 b&w 8" drivers and the 1" tweeter.

|

rs1297c inside shot

|

exhaust-port for vacuum motor. note the hinge outline on the cabinet door and the crude box that housed my variac. the box/variac and cabinet door came from the dumpster.

|

|

straight-on view of version #3

|

Image

|

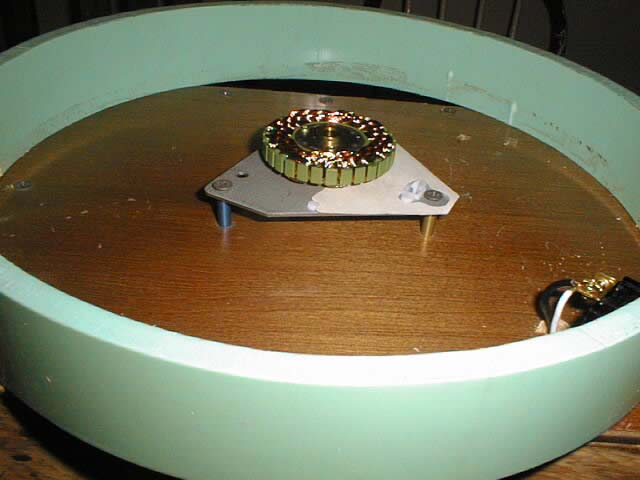

motor and mount assembly from thriftstore tt. had to put it on top as there was no room in the box and used the 12"pvc ring for cosmetic purpose only.

|

|

version #4 with scan speak subs

|

Image

|

detail of velvet-covered slot and hole that fits over spindle to keep vacuum arm from rotating with the record. slot is 11cm long and about 2mm wide made with 2 stacked cutting disks on my ryobi hobby tool. velvet is adhered with double-sided tape from hardware store.

|

|

version #4 speakers in listening position

|

cobbled stand from a bunch of leftover parts !

|

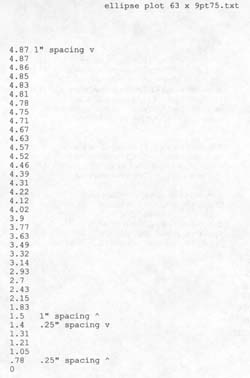

newbies plot numbers for 63" x 9.75" ellipse

|